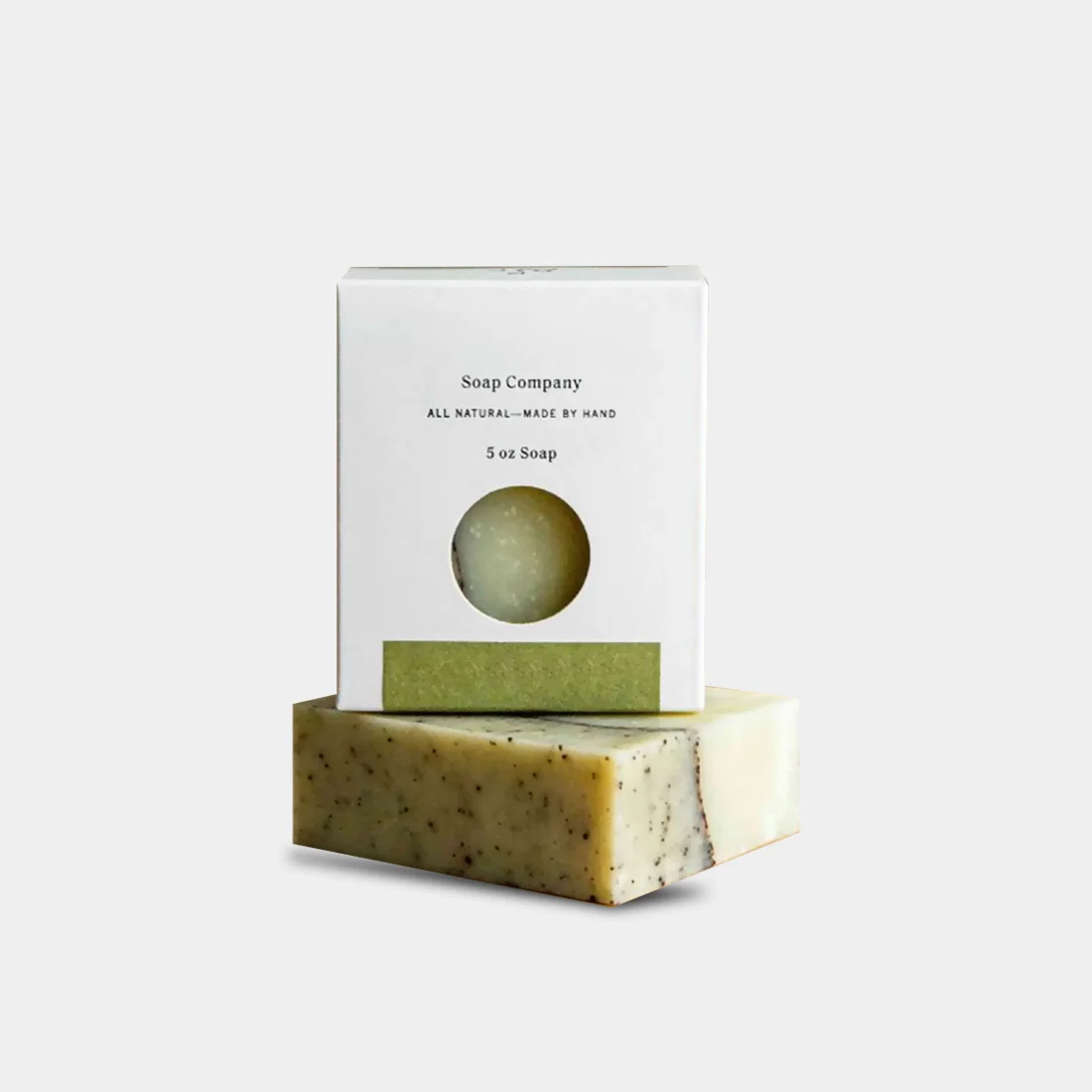

Window Soap Boxes — Eye-Catching Visibility, Secure Protection

Customers buy with their eyes (and nose). Window soap boxes let shoppers see the swirl, botanicals, and texture that make your bars unique—without handling every piece. We engineer each carton around your bar dimensions and display plan: retail peg, tray, or stacked shelf. Vented die-cuts boost scent throw for essential-oil recipes, while closed windows protect salt bars and exfoliant inclusions from abrasion. For small-batch runs, we print digitally to hit quick launch dates; for scale, offset delivers flawless solids and tight type. Choose plastic-free open windows for curbside recyclability, or add a clear film to keep soap dust off and sharpen the view. With structural options like STE/RTE and auto-lock bottoms, you’ll get a box that loads fast, ships flat, and stands square—because unboxing should be as satisfying as the first lather.

Key Benefits & Features

-

Show more, sell faster: Precision die-cut windows spotlight swirl patterns and botanicals, improving grab-and-go appeal.

-

Built for soap realities: Oil- and abrasion-resistant coatings help cartons stay clean during curing, packing, and transit.

-

Right fit, fewer returns: CAD-fit structures around your exact bar reduce rattle, corner crush, and scuffing.

-

Brand-true color: CMYK + Pantone® matching ensures label-law legibility and consistent brand solids across SKUs.

Industry Applications — Where Window Boxes Win

-

Artisan & Farmers’ Market Brands: Open or micro-vented windows let natural scents diffuse, helping shoppers compare fragrances without unwrapping.

-

Natural/Organic Retail: Kraft or uncoated stocks + minimal ink coverage reinforce clean-label positioning while the window proves what’s inside.

-

Spa & Wellness: Soft-touch finishes and subtle foil accents elevate giftability; film windows keep linen closets free of soap dust.

-

Hotel Amenities & Hospitality: Compact STE formats with batch and date space improve housekeeping control and inventory rotation.

-

Subscription & DTC: Strong 20–24 pt boards resist compression in mailers; windows reassure first-time buyers that the shade and inclusions match the product page.

Material Options & Properties

Soap boxes face unique stresses: oil transfer, abrasion from salts/herbs, and occasional moisture. We recommend SBS (solid bleached sulfate) for crisp color and smooth touch, or unbleached kraft for a natural look that hides handling marks.

For gift lines, coated two-side (C2S) boards balance print quality with scuff resistance. Window choices include open die-cut (plastic-free), cellulose film (plant-based, breathable look), or PET film (crystal-clear, durable). If your bars are heavily superfatted or salt-cured, add a grease-resistant aqueous or dispersion coating. All paperboard options are available with FSC® chain-of-custody on request.

Material Comparison

| Material | Best For | Properties | Benefits | Eco Performance |

|---|---|---|---|---|

| SBS 16–24 pt | Premium retail, fine graphics | Smooth, high-opacity, tight folds | Sharp print, clean edges | Widely recyclable; FSC option available |

| Kraft (Unbleached) 18–24 pt | Natural/organic lines | Stiff, tactile fibers, hides scuffs | Rustic look, strong shelf cues | Recyclable; FSC option available |

| C2S 18–24 pt | Gift sets, heavy ink | Coated both sides; scuff-resistant | Saturated color, smoother interiors | Recyclable; FSC option available |

| Cellulose Window (optional) | Plastic-free view | Transparent, plant-based | Premium clarity without PET | Check local programs; plastic-free box if omitted |

| PET Window (optional) | Max clarity/durability | Crystal-clear, tear-resistant | Protects bar, no fiber fray | Remove film before recycling (local guidance varies) |

Printing & Branding Options

Print full-coverage CMYK, add spot Pantone® for brand solids, or run economical 1–2 spot colors on kraft. We support digital (short runs/SKU variety), offset litho (retail-grade color), and flexo for very large volumes. Need exact brand hues? Pantone® matching is available with no fee—ideal for color-critical soap lines and compliance icons.

Branding tips: Reserve a low-ink or unprinted “peek band” around the window to prevent edge scuff. On kraft, increase type size and use higher-contrast spot colors for ingredient panels. For multi-bar assortments, color-code flavor icons (e.g., lavender, citrus) and maintain fixed positions to speed shelf resets.

Finishes & Specialty Effects

Select matte aqueous for a modern, low-glare look that hides fingerprints; add anti-scuff for markets with heavy handling. Soft-touch lamination creates a spa-grade feel that pairs beautifully with uncoated kraft accents. Want sparkle for gifting? Foil stamping (hot or cold) on logo locks-up—kept away from fold lines—delivers shine without compromising runnability. Spot UV gloss around the window adds contrast and draws the eye without flooding the entire panel.

Styles & Customization — Structures That Load Fast & Display Clean

-

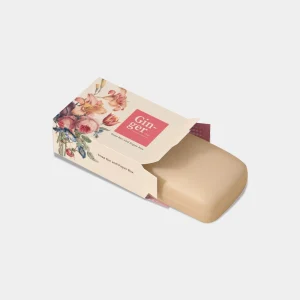

Straight Tuck End (STE): Clean facing panels; ideal for peg/shelf display.

-

Reverse Tuck End (RTE): Efficient board yield; great for compact bars.

-

Auto-Lock Bottom: Faster hand-fill for 4–5 oz bars; stands square in trays.

-

Window Options: Open die-cut, die-cut + cellulose film, or PET film; add micro-vents to boost scent throw.

-

Hang Tabs/Euro-slots: Retail-ready without additional cards.

-

Security & Logistics: Glue assists for faster assembly; batch-code and UPC zones standardized across SKUs for compliance.

Sizing & Technical Specs

Measure your finished-cured bar (L × W × H) and add 1/16–1/8 in working clearance per axis depending on bevels and texture. We design to ±1/32 in dieline tolerances on panel dimensions; window registration typically ±1/64 in relative to keylines. For heavier, salt-cured, or exfoliant bars, step up to 20–24 pt and consider auto-lock bottoms. Avoid windows that cut through scoring zones to maintain squareness. UV exposure can fade natural dyes—use kraft or add inside print to reduce show-through.

Design Guidance — Artwork That Prints Clean & Cuts True

-

Dielines: Keep critical text ≥1/8 in from all cut/score lines; 1/4 in from window edges.

-

Window framing: Add a 0.04–0.06 in bridge around complex shapes to maintain strength.

-

Ink & kraft: Use high-contrast palettes; overprint white only where necessary to preserve the kraft character.

-

Small type: Ingredients/legal set ≥6.5–7 pt on white; ≥8 pt on kraft or reverse; increase leading by 10–15%.

-

Finishes: Reserve foil/UV away from scores by ≥1/8 in to prevent cracking; specify vector paths for foil.

-

Files: Provide press-ready PDF/X-1a with embedded fonts, CMYK/spot defined; 300 dpi images; 0.125 in bleeds; separate layers for dieline, crease, window, and white ink (if used).

-

Color: Supply Pantone® callouts for brand solids; we match at no fee.

Ordering & Pricing — Simple, Fast, Transparent

-

Send bar dimensions, quantity, and artwork.

-

We provide a custom dieline and digital proof by default.

-

Approve proof; we produce and ship.

MOQ: 100 units. Standard lead time 10–12 business days after proof; rush 6–8 days available. Pantone® matching: no fee. Physical pre-production sample (optional): $100, 3–4 days.

Quality & Compliance

Every order goes through dieline review, prepress checks, and color verification. Paperboard options are available with FSC® chain-of-custody on request. We allocate dedicated real estate for required markings: net wt, ingredients (INCI), batch/LOT, and scannable UPC/QR. For bath/cosmetic labeling, we follow typical U.S. panel conventions; please provide your regulatory text.

Ask us to reserve extra clearance for warehouse labels and date codes to streamline QA.

Sustainability Commitment — Right-Sized & Plastic-Smart

We right-size cartons to reduce board usage and freight. Paperboard structures are widely recyclable in curbside programs; choosing no film windows keeps the entire pack plastic-free. If you need clarity, cellulose windows offer a plant-based look; PET windows provide durability—remove the film where local programs require it before recycling. FSC® options are available to support responsible fiber sourcing.

Case Study — Boutique Brand, Retail Upgrade

A boutique soap maker transitioning from sleeves to window cartons needed stronger shelf impact and cleaner handling. We engineered an STE carton in 20 pt SBS with a rounded-corner window and anti-scuff matte. The window sat 3/16 in from scores to preserve rigidity; micro-vents along the top panel helped fragrance projection.

After rollout, wholesale partners reported smoother planogram compliance and fewer open-shelf testers. The brand later extended the system to seasonal SKUs by swapping foil colors while retaining the same dieline to control costs.

Comparison & Alternatives — Window Box vs. Sleeve vs. Full Wrap

-

Window Soap Box: Best for retail where visibility, protection, and labeling space matter. Add film for dust control, or go open for plastic-free packs.

-

Paper Sleeve: Lowest material use and cost; ideal for markets where shoppers can handle bars. Limited surface area and less edge protection.

-

Full Wrap / Glassine Bag: Great for scent containment and gift sets; fewer display panels and higher material usage.

Choose window cartons when you need a premium look, UPC space, and structured stacking. Choose sleeves for budget SKUs or markets favoring touch. Use wraps when shipping fragranced bars in humid climates.

Why Brands Choose Us?

You get senior-level packaging engineering, fast proofs, and production that hits dates. Secure U.S. contact, clear policies, and consistent color across SKUs reinforce retail trust. FSC® options, short MOQs, and rush lead times mean you can test, learn, and scale without waste.

Frequently Asked Question (FAQs)

Q: Can you make plastic-free window soap boxes?

A: Yes. Choose an open die-cut (no film) or specify cellulose film. The box remains curbside recyclable when no film is used; cellulose acceptance varies locally—ask your hauler.

Q: Will oils from my bars stain the box?

A: Use SBS/C2S with a grease-resistant aqueous coating. For heavy superfats or scrub bars, step up board weight and keep windows clear of score lines.

Q: Can you match my brand’s Pantone® exactly?

A: Yes—Pantone® matching at no fee. Provide coated/uncoated callouts; we’ll hit target LAB values under standard lighting.

Q: What’s the fastest I can get boxes?

A: Standard production is 10–12 business days after proof approval; rush 6–8 days is available. Transit time depends on ship-to.

Q: Do you provide samples?

A: Digital proof is standard. Optional physical pre-production sample: $100, produced in 3–4 days.

Q: What’s the minimum order?

A: MOQ is 100 units for custom-printed soap boxes—ideal for launches and seasonal trials.

Ready to let your bars shine? Send your bar dimensions and artwork for a free dieline and print check. We’ll recommend the right window style, board weight, and finish—then produce retail-ready cartons on your timeline. Emailcontact@printives.com or call +1 (929) 659-6325.

Kelsey T. (verified owner) –

Customers can actually see the texture of my handmade bars. That makes a huge difference!

Skylar C. (verified owner) –

Ordered 1,200 pieces. Every box was consistent, no misprints, no bad folds. Great job!

Morgan F. (verified owner) –

Overall great quality, but a couple of boxes had slightly scratched windows. Still usable though.

Madelyn G. (verified owner) –

I wasn’t sure if the window option was worth it, but after trying these, I’ll never go back.

Cassidy H. (verified owner) –

Love the natural kraft with a peek window. Makes handmade soaps feel boutique-ready.

Camila N. (verified owner) –

Ordered 500 to test. They look so much better in person. I’ll be upgrading my entire line.

Lila M. (verified owner) –

The boxes protect my soaps and still showcase their colors beautifully. Customers love them.

Hope D. (verified owner) –

Quick delivery and excellent packaging quality. Not a single box damaged in transit.

Tessa W. (verified owner) –

The transparent window is a hit at markets — customers like seeing the actual bar inside before buying.

Delaney S. (verified owner) –

My soaps finally look professional. These boxes give me confidence to approach new retailers.

Alana P. (verified owner) –

Lightweight, eco-friendly, and stylish. Exactly what I wanted for my natural soap brand.

Kendall B. (verified owner) –

Folded easily, stored flat, and assembled without hassle. Will be ordering again.

Dana L. (verified owner) –

Ordered 800 boxes. Sturdy material, clean cuts, and the clear window is perfectly placed. Very satisfied.

Paige K. (verified owner) –

Clean look, strong enough for shipping, and attractive enough for display. Great value.

Felicity R. (verified owner) –

The window cut makes my soaps look so inviting. Customers always comment on how pretty they look.

Piper J. (verified owner) –

Simple yet elegant. These boxes elevated my entire product line.

Elise V. (verified owner) –

Perfect fit for my soaps, no extra wiggle room. The window makes it feel modern and classy.