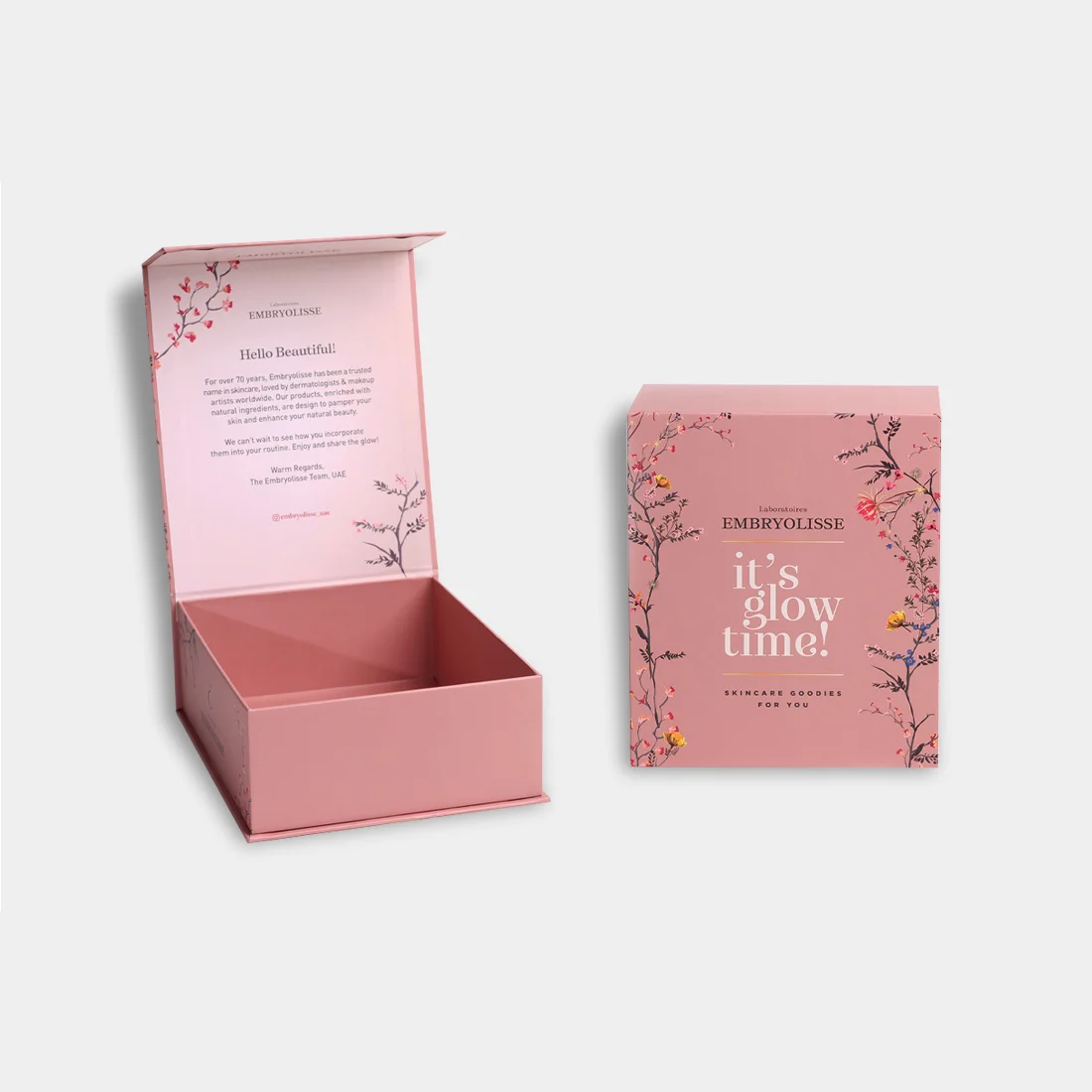

Conversion-Driving Makeup Boxes

In beauty, secondary packaging does heavy lifting: it cues shade families, communicates ingredients, and earns the lift-off from shelf to basket. We design makeup cartons that balance aesthetics with engineering—tight tolerances, scuff-resistant coatings, and inserts that hold compacts, droppers, and tubes precisely. Paperboard thickness is specified in points (pt), where 1 pt = 0.001 in, so your 18- or 24-pt choices translate cleanly to protection and hand-feel.

For complexion lines or holiday kits, add window patching (including cellulose-based films) to preview texture without breaking seals. We pair brand-true color with production pragmatism: dielines that fold cleanly on high-speed lines, coatings that resist fingerprints, and compliant panel layouts that meet US cosmetic labeling rules on PDP, net contents, and INCI.

Key Benefits & Features

-

Retail-ready structure: 14–24 pt SBS or kraft for lip, eye, and face SKUs; rigid set-ups for premium kits.

-

True-to-shade color: CMYK + Pantone® matching; inside/outside print for storytelling.

-

Secure fit: Paperboard or foam inserts prevent rattling and breakage during fulfillment.

-

Brand-elevating finishes: Soft-touch, foil, and spot UV that resist scuffs and photograph beautifully.

-

Compliance-friendly panels: Layout guidance for PDP, net contents (US + metric), and INCI lists.

Industry Applications

-

Color Cosmetics: Slim tuck-end cartons for lipsticks/liners; palettes in 18–24 pt with reinforced ends to protect pans from chipping.

-

Skincare & Serums: Dropper-bottle cartons with scored crash-locks and U-card inserts to stop vertical drift during parcel shipping.

-

Fragrance & Mists: Rigid set-up or 24-pt folding cartons with neck braces; soft-touch + foil to signal premium positioning.

-

Clean/Indie Brands: Uncoated kraft or low-ink designs with compostable window films to telegraph sustainability without sacrificing visibility.

-

Subscription & DTC Kits: Corrugated mailer + retail-box combo; carton calipers chosen for unboxing glamour yet efficient cube utilization.

Material Options & Properties

| Material | Best For | Properties | Benefits | Eco Performance |

|---|---|---|---|---|

| SBS (C1S/C2S) 14–24 pt | Most makeup cartons | Smooth, high-brightness; 1 pt = 0.001 in | Sharp print; crisp creases | Curbside recyclable in most US communities |

| Kraft (Unbleached) 16–22 pt | Naturals/clean lines | Natural brown fiber | Earthy aesthetic; hides scuffs | Recyclable; higher PCW options available |

| Premium Rigid (Wrapped chipboard) | Gift sets/fragrance | 60–100 pt board wrapped with print | Luxury feel; strong corners | Board is recyclable; magnets removable on request |

| Corrugated E/F-flute | E-comm ship-in-own-container | Lightweight, crush-resistant | Survives parcel abuse; printable | Widely recyclable |

| Cellulose/Acetate Window Film | Shade preview windows | Clear, patch-applied films | Product visibility; tamper-evident | Cellulose/acetate options are compostable; verify locality. |

Notes: Typical makeup boxes use 14–24 pt paperboard; choose heavier calipers for glass or multi-unit loads.

Printing & Branding Options

-

Methods: Offset (best color fidelity), digital (short-run, variable), and flexo for large volumes.

-

Color: CMYK process + Pantone® spot matching at no fee for key brand hues (e.g., signature lipstick shade).

-

Surfaces: Outside-only (4/0), inside/outside (4/4) for surprise reveals or ingredient storytelling.

-

Branding tip: For complexion lines, add micro-text or fine halftones near PDP to differentiate similar SKUs while maintaining a consistent wall of color.

Finishes & Specialty Effects

Choose targeted accents over blanket effects:

-

Soft-Touch Laminate for velvety hand-feel that hints at skincare sensorials.

-

Foil Stamping (Gold/Rose/Transparent) for logos and shade numbers that pop under retail LEDs.

-

Spot UV / Raised UV on product silhouettes to contrast with matte fields.

-

Window Patching (clear or cellulose film) for shade preview without opening.

Makeup Boxes Styles & Inserts

-

Straight/Reverse Tuck End (STE/RTE): Efficient, ideal for slim SKUs.

-

Auto-Lock Bottom: Added stacking strength for heavier glass.

-

Sleeves & Belly Bands: Seasonal refresh without retooling the primary carton.

-

Rigid Set-Up with Lift-Off Lid or Book-Style: Giftable kits with foam/paper inserts.

-

Windows (die-cut or patched): Shapes tailored to compacts/pans; maintain adequate glue lands per window size.

Makeup Carton Specs & Tolerances

- Measurement guidance: All sizes are inside dimensions: Length (shelf-front) × Width (shelf-depth) × Depth/Height. Typical converting tolerance ±1/16 in (±1.6 mm).

- Paperboard caliper: 14–24 pt common for makeup; 1 pt = 0.001 in. Approx. conversions: 18 pt ≈ 0.018 in (≈0.456 mm) and ≈361 gsm; 24 pt ≈ 0.024 in (≈0.610 mm) and ≈454 gsm. Use 18–24 pt for glass bottles/palettes; 14–16 pt for slim tubes and pencils.

- Windows: Maintain frame strength around die-cuts; specify film (acetate/cellulose) and patch size. Larger windows need stiffer films and wider glue lands.

- Coatings: Aqueous gloss/matte for scuff control; soft-touch laminates for premium lines.

- Pack-out: Request inserts when void space >3 mm; choose paperboard “U” braces for recyclability or foam for complex geometries.

Design Guidance for Custom Makeup Boxes

-

PDP hierarchy: Brand mark → product name/shade → net contents (US + metric) → claims; keep contrast ≥4.5:1 for legibility.

-

Regulatory panels: Back/side panels for ingredient (INCI) list and manufacturer/distributor; reserve clear space for UPC, batch/lot, and PAO symbol.

-

Net quantity statement: On the principal display panel, shown in US customary and metric units per FPLA.

-

Color control: Provide Pantone codes and print-ready PDFs with 0.125 in bleeds; embed fonts, outline strokes, and supply images at 300 ppi minimum.

-

Window shapes: Avoid acute corners <2 mm radius; add 0.25 in glue lands for reliable window patching.

How to Order Custom Makeup Boxes?

-

Pick size, material, and style.

-

Upload artwork or request a dieline.

-

Approve digital proof (physical sample optional).

MOQ: 100 units. Standard lead time: 10–12 business days after proof. Rush: 6–8 days. Pantone® matching: included. Physical sample: $100, 3–4 days. Talk to our team for volume breaks and kitting.

Quality & Compliance

We build to tight converting tolerances and proof color against approved drawdowns. For US cosmetics, ensure cartons meet FDA cosmetic labeling in 21 CFR Part 701 (INCI, manufacturer/distributor, warnings as applicable) and FPLA for net contents on the PDP (US + metric). We provide dieline callouts; final compliance remains brand’s responsibility.

Eco Makeup Packaging Options

Choose FSC® chain-of-custody paperboards on request and design for recyclability (single-material cartons, paper inserts, minimal laminates). Where visibility matters, we can specify cellulose-based window films or paper/glassine alternatives to reduce plastics while preserving clarity. Verify local recycling/composting rules for films and foils.

Case Study: Makeup Box Rebrand Example

An indie clean-beauty label moved from generic white 16-pt cartons to 18-pt kraft with soft-touch + white ink, adding a cellulose window for shade preview. Result: fewer scuff returns in 3PL handling, a faster shelf read (PDP hierarchy clarified), and a 17% lift in planogram compliance reported by the retailer’s audit—without changing the primary packaging. (Data anonymized; structure and material choices mirror typical outcomes we see when upgrading caliper and finishes.)

Comparison & Alternatives

-

Folding Cartons (14–24 pt): Best for most makeup SKUs; lowest cost per unit; fully printable; ships flat.

-

Rigid Set-Up Boxes: For gift sets or prestige launches; highest perceived value; stores assembled; higher unit + freight.

-

Corrugated Mailers: For DTC ship-in-own-container; add an internal folding carton for retail-ready presentation.

Tip: Choose folding cartons for velocity SKUs; rigid for hero products; mailers when shipping protection outweighs shelf density.

Why Brands Choose Us?

US-based team, packaging-engineer oversight, low MOQs, fast lead times, and color control with included Pantone matching. FSC options and compliance-friendly dielines de-risk launches while keeping budgets predictable. One point of contact from dieline through delivery.

Frequently Asked Questions (FAQs)

Q: What thickness should I use for glass bottles or palettes?

A: 18–24 pt SBS or kraft with auto-lock bottoms; add inserts for weight distribution.

Q: Can you print inside the box?

A: Yes—outside only (4/0) or inside/outside (4/4) for shade stories or QR how-to panels.

Q: Do you match Pantone® brand colors?

A: Yes, Pantone matching is included; supply codes and target swatches/drawdowns.

Q: Are window films recyclable or compostable?

A: Cellulose/acetate options are compostable; check local rules. PET is recyclable in some streams; paper/glassine “windows” are an alternative.

Q: What must appear on my makeup carton?

A: PDP net contents (US + metric), INCI ingredient list, and manufacturer/distributor details; add warnings if applicable per 21 CFR 701/740.

Q: Do you offer rush?

A: Yes—6–8 business days after proof approval, subject to schedule.

Ready to launch prettier, stronger makeup boxes? Send size, style, and artwork for a same-day DFM check and dieline. MOQ 100; 10–12 day standard lead time with Pantone® matching included. Request a $100 physical sample to validate fit before full run.

Reviews

There are no reviews yet.