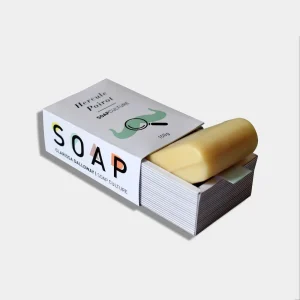

Rustic Look, Retail-Ready Impact — Custom Kraft Soap Boxes

Great soap deserves packaging that works as hard as it looks. In 2025, US shoppers say packaging should do the practical things best: provide clear label information, stay durable through handling, and be easy to recycle—with recyclability the top sustainability attribute (77% call it extremely or very important according to Mckinsey). Globally, a majority of consumers in every country reports being willing to pay more for sustainable packaging (roughly 40% in Japan to 85% in India), led by Gen Z and Millennials—proof that credible materials and clear disposal cues can translate to value.

That’s why our kraft soap boxes are engineered for performance and persuasion: FSC-capable paperboard, tight dielines that load fast, generous INCI/lot/UPC zones, and die-cut windows that showcase texture while protecting edges. Add white-ink underlays for crisp color on kraft and you get a natural, premium look that also signals the sustainability cues buyers reward.

Kraft Soap Box Advantages

-

Authentic shelf signal: uncoated kraft fibers cue natural/handmade positioning; optional white-ink underlays keep color accurate on brown stock.

-

Engineered fit: custom die-lines tuned to your bar’s true dimensions with 1/16–1/8 in working clearance for fast packing.

-

Window options: die-cut shapes; optional clear/plant-based film to deter abrasion and shop dust.

-

Print your way: CMYK + free Pantone® matching; inside print, batch/INCI panels, UPC/QR, and compliance space ready.

Who Uses Kraft Soap Packaging?

-

Artisan & cold-process brands: earthy kraft aligns with small-batch storytelling; die-cut windows highlight marbling while shielding edges.

-

Natural skincare lines: brown stock + white ink creates a clean clinical-meets-botanical look without plastic.

-

Farmers’ markets & pop-ups: rigid enough to stack in crates; quick-load STE/RTE flaps speed hand-packing between customers.

-

Hotel & amenity programs: compact, scuff-resistant boxes maintain presentation after bulk handling; add batch code/lot traceability.

-

Subscription & e-commerce: snug internal clearances keep bars from bruising in mailers; panel space for QR-driven unboxing and re-orders.

Material Options & Properties

Kraft isn’t one material—it’s a family. We help you choose the right sheet for print clarity, stiffness, and the “feel” your brand needs.

Material Comparison

| Material | Best For | Properties | Benefits | Eco Performance |

|---|---|---|---|---|

| Natural (unbleached) kraft 18–24 pt | Rustic/natural brands, bold graphics | High stiffness; visible fiber; lower ink holdout | Tough, hides handling marks; tactile | Widely accepted in U.S. curbside paper streams; check local rules. |

| Clay-coated kraft (C1S) 16–22 pt | Finer type, photo elements | Smooth print side; kraft back; better ink density | Sharper detail while keeping kraft back | Paperboard recycling widely available; confirm locally. |

| Kraft w/ wet-strength sizing | Humid retail or steamy bathrooms | Moisture-resistant sizing; stiffer when damp | Resists warping, edge feathering | Recyclability depends on local MRF; remove plastic films before recycling. |

| FSC®-certified options | Verified responsible sourcing | Chain-of-custody documentation | Supports ESG claims, optional on-pack FSC marks | Available on request via Printives. |

Printing & Branding Options

Offset and digital printing are both supported. We’ll convert your brand colors for kraft: light hues and pastels can mute on brown stock; add a white-ink underbase or switch to coated kraft for spot-on Pantones (we include Pantone® matching at no fee). For earthy lines, lean on high-contrast inks (rich black, deep greens) with fine-line botanical illustrations. For clean beauty, pair white-ink logos with minimal copy and a tight window to show bar texture. Inside-panel printing welcomes rituals, INCI, and QR care guides.

Finishes & Specialty Effects

Choose effects that complement kraft’s texture:

-

Matte aqueous varnish for rub resistance without plastic gloss.

-

Foil stamping (gold/copper/clear) to create premium contrast on brown stock.

-

Deboss/emboss logos for tactile brand recall.

-

Spot UV over white-ink for a crisp, modern pop on titles.

Styles & Customization

-

STE / RTE cartons: fast to load; ideal for 3–5 oz bars.

-

Auto-lock bottom: adds crush strength for heavier/salt bars.

-

Sleeves & belly-band kits: lower material use; keep full fragrance.

-

Windows: ovals, arcs, brand marks; optional clear or plant-based film.

-

Retail features: hang tabs, tamper slits, tear-strips, batch-print areas.

Sizing & Technical Specs

Measure the longest edge (L) × shortest face (W) × bar thickness (D). Add 1/16–1/8 in working clearance to speed packing and allow for seasonal bar swell. Typical board for soap: 16–24 pt (approx. 300–450 gsm); we’ll select caliper by bar density and shipping method. Grain runs along the longest panel to prevent lid curl. Windows are reinforced with a 1/8 in land to keep edges clean. Tuck flaps use friction locks; request dust-flaps for travel sets. Not intended for water immersion; for wet-room retail, add wet-strength sizing and an aqueous topcoat.

Spec Table (core)

-

Board: 16–24 pt kraft; coated (C1S) optional

-

Print: CMYK + Pantone®; white-ink underbase as needed (no-fee PMS match)

-

Tolerances: ±1/32 in die-cut; ±0.5 mm score/fold

-

Windows: die-cut; clear/plant-based film (optional)

-

Finishing: trim, fold, glue; packed flat

Design Guidance

Use high-contrast palettes or a white-ink flood beneath brand colors for fidelity on brown stock. Keep typography ≥7 pt on uncoated sheets; fine hairlines should be ≥0.3 pt. Place INCI, net wt., and batch/lot on one panel; keep UPC/QR on a flat surface clear of folds. Provide vectors (PDF/X-1a or AI), fonts outlined, images 300 ppi at size, and a 0.125 in bleed. For windows, keep critical art ≥0.125 in from the die-edge. If using essential-oil claims, allocate space for regulatory copy as required in your sales regions.

How to Order Kraft Soap Boxes

-

Send size + bar photos.

-

Choose material/finish.

-

Upload artwork for proof.

-

Approve digital proof; optional paid physical sample ($100, 3–4 days).

-

Production & ship.

MOQ 100; standard lead time 10–12 business days, rush 6–8. Pantone® matching included. Contact: +1 (929) 659-6325 or contact@printives.com.

Quality & Compliance

FSC® chain-of-custody available on request for verified sourcing. Every order includes a pre-production proof; structural die-lines are checked for loading clearance and glue flap integrity. We can reserve space for ingredient, net weight, and batch/traceability panels per your market’s cosmetic/soap labeling norms.

Eco-Friendly Kraft Soap Boxes

Kraft paperboard is fiber-based and widely accepted in U.S. curbside recycling programs—always check local rules. We also offer FSC® options and right-sized structures to reduce waste. Many U.S. consumers say they’ll pay a premium for sustainable packaging—smart design helps you capture that value without over-packaging.

Case Study – Kraft Soap Box Success

An emerging cold-process brand selling at weekend markets struggled with scuffed bars and slow hand-packing. We switched them from sleeves to a 18-pt STE kraft box with oval window and added an inside “ritual” panel. Results: faster pack time, sturdier stacks in bins, fewer damaged bars in transit, and notably more shoppers picking up boxes to read the story—then buying.

Comparison & Alternatives

-

Kraft boxes vs. Sleeve: Boxes protects edges, offers more copy space, and stacks better; sleeves minimize material and keep more fragrance exposure—best for shrink-wrapped bars.

-

Kraft vs. white SBS: Kraft signals natural/handmade and hides handling marks; SBS yields the sharpest photos and brighter Pantones. Choose SBS if you need clinical cosmetics aesthetics; choose kraft to emphasize eco / rustic positioning.

-

Kraft box vs. paper wrap: Wrapping papers are lowest-material but offer less impact protection and retail facings.

Trusted Kraft Soap Boxes Manufacturer

Engineer-led dielines, quick proofs, free Pantone® matching, FSC® options, and small-friendly MOQs—backed by responsive U.S. support. We build boxes that look right and load fast, so your team spends time selling, not fighting cartons.

Frequently Asked Question (FAQs)

Q: What board thickness works best for 4 oz bars?

A: Most 3–5 oz bars are well served by 18–22 pt kraft. Dense/salt bars or e-commerce-heavy brands may prefer 24 pt for crush resistance.

Q: Can you print bright colors on brown kraft?

A: Yes—use a white-ink underbase beneath spot areas or select coated (C1S) kraft for higher ink holdout. We include Pantone® matching at no fee.

Q: Are kraft soap boxes recyclable?

A: Paperboard is widely accepted in U.S. curbside programs, but always confirm locally and remove any plastic window films before recycling.

Q: Do you offer sustainable material options?

A: Yes—FSC® chain-of-custody stocks are available on request; right-sizing and minimal coatings further improve recyclability.

Q: What’s the fastest I can get custom boxes?

A: Rush production is typically 6–8 business days after proof approval; standard is 10–12. Physical pre-production sample available in 3–4 days.

Q: Can you add windows in custom shapes?

A: Absolutely—ovals, logos, arcs, or multi-apertures. We keep a 1/8 in land around cuts for strength; optional clear or plant-based film adds dust protection.

Ready to give your soap the natural-premium look it deserves? Send your bar size and a quick photo—we’ll return a dieline and proof fast. Get a custom quote today and ship production in as little as 6–8 days with rush.

Kendra O. (verified owner) –

These fold flat, save storage space, and still assemble easily. Exactly what I needed for small orders.

Savannah B. (verified owner) –

Strong material, holds up well even in humid weather. Customers noticed the eco touch.

Kristen C. (verified owner) –

Love that they’re eco-friendly while still looking professional. Big hit with my customers.

Hailey X. (verified owner) –

Eco-friendly and stylish. Exactly what I wanted for my eco-conscious brand.

Megan V. (verified owner) –

I’ve tried a few suppliers, but these kraft boxes stand out for their consistency and strength.

Jenna K. (verified owner) –

Quick to assemble and they hold their shape well. Great experience so far.

Whitney M. (verified owner) –

Perfect rustic look. Customers compliment the packaging almost as much as the soap itself.

Brianna Z. (verified owner) –

Solid purchase. They’ve upgraded the entire presentation of my products.

Joanna I. (verified owner) –

I ordered 25,000 boxes for my wholesale order and everything came just as promised. Highly satisfied.

Cassandra V. (verified owner) –

Clean kraft look with no smudges or uneven cuts. Very happy with the results.

Kristen U. (verified owner) –

Rustic charm with clean lines. Customers think my soaps look farmers market chic. I’m thrilled.

Melanie Y. (verified owner) –

Minimalistic yet elegant design. Exactly the aesthetic I was aiming for.

Madison G. (verified owner) –

These kraft soap boxes feel natural and sturdy. Perfect fit for my handmade lavender soaps.

Alexis L. (verified owner) –

Love the eco look, but a few had slightly rough edges. Still using them though.

Autumn B. (verified owner) –

These boxes give my soaps a high-end natural appeal without being flashy. Perfect match for my brand.

Jordan Y. (verified owner) –

Ordered 400 boxes to test quality. Definitely ordering more after seeing the results.

Riley L. (verified owner) –

Packaging was neat, delivery was fast, and the quality was outstanding. 5 stars!

Megan Q. (verified owner) –

Lightweight but sturdy. Ideal for my online orders and farmers’ market sales.

Madison W. (verified owner) –

Perfect for gift sets too – my soaps look beautiful packaged in these kraft boxes.

Brittany Q. (verified owner) –

Great natural look. Customers say it makes the soaps look artisanal and handcrafted.

Bailey G. (verified owner) –

My 11,000-piece order came faster than expected. Every box was the same quality – consistent and reliable.

Kendra P. (verified owner) –

Affordable, durable, and attractive. A great combo for a small business like mine.

Madison I. (verified owner) –

Boxes shipped flat, which saved me so much space in storage. Easy to put together too.

Bailey V. (verified owner) –

The natural brown kraft color goes perfectly with my botanical soap line.

Shelby Q. (verified owner) –

Some boxes were a little snug for larger bars, but overall fantastic quality.

Amber G. (verified owner) –

The kraft texture really highlights the natural vibe of my handmade soaps. Very impressed.

Holly G. (verified owner) –

Even after shipping across states, the boxes held up perfectly. Very reliable quality.

Holly W. (verified owner) –

Ordered 6000 pieces. Every single one came flawless. The earthy look works so well with my organic brand.

Danielle D. (verified owner) –

Beautiful, simple, and effective. Can’t ask for more in a soap box.