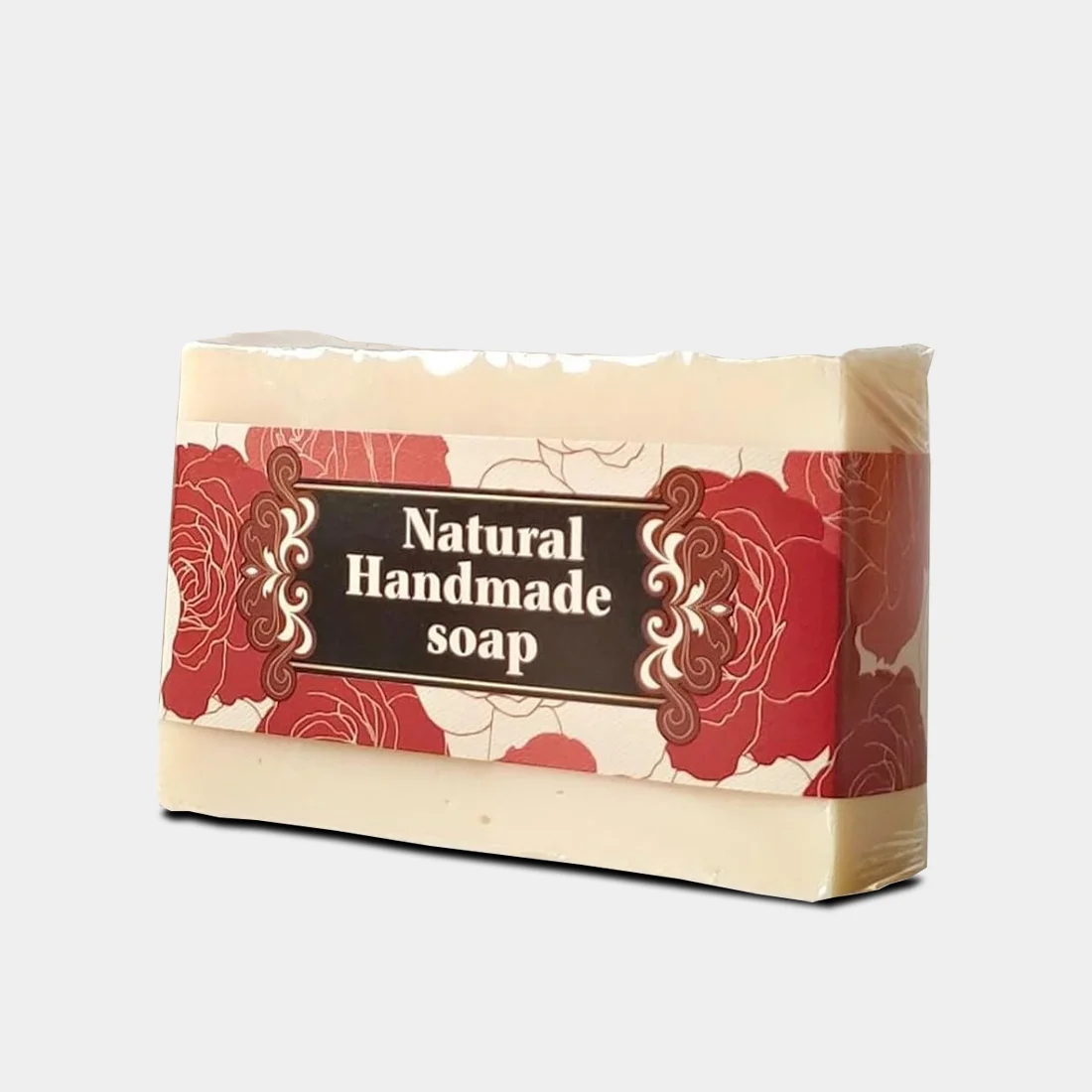

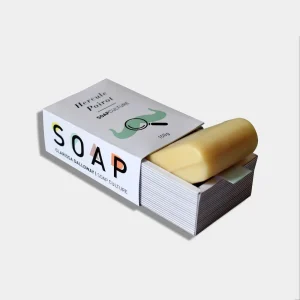

Clean, secure, store-ready — Custom Soap Sleeve Packaging

Soap sleeves deliver the sweet spot between minimal material and maximum shelf presence. For most artisan bars, a well-sized sleeve adds rigidity, protects edges, and gives you a 360° canvas for ingredients, batch codes, and branding—without hiding the product’s texture or swirl. Typical sleeve stocks span roughly 12–28 pt, covering everything from earthy Kraft to smooth SBS for photo-quality print.

Measuring is simple: wrap paper around a fully cured bar (so dimension changes from drying don’t surprise you), mark the overlap, and add allowance for the seam or tape. With our Pantone matching at no extra fee and fast lead times, you can lock brand color and hit launch dates without over-packaging.

Key Benefits & Features of Soap Sleeves

-

Material-lite, brand-heavy: Big branding area with less board than full cartons—cuts weight and cost.

-

Engineered fit: Sized to your exact bar; optional peel-and-seal tape speeds hand-assembly.

-

Retail-ready compliance: Space for INCI, net wt., batch/UPC, and required font sizes.

-

Premium finishes that sell: Matte/soft-touch, foil, emboss, and precise die-cut windows to showcase texture.

Soap Sleeve Packaging by Industry

-

Artisan & natural skincare: Kraft or uncoated stocks telegraph “handmade” and sustainability; windows highlight botanicals.

-

Hotel & hospitality guest soaps: Tight-tolerance sleeves stay put in transit, offer scannable codes for amenity programs.

-

Subscription boxes: Flat-shipped sleeves minimize kitting time; batch codes + SKUs speed QC.

-

Farmers’ markets & pop-ups: Quick to assemble on-site; sleeves double as price tags and ingredient disclosures.

-

Boutiques & gift shops: Soft-touch with foil elevates gifting; custom die-cuts align with seasonal campaigns.

Soap Sleeve Material Options & Properties

Sleeves work best with paperboards that crease cleanly and hold friction. Choose surface and stiffness by how your bars are wrapped (naked vs. paper-wrapped) and the desired print look. Typical workable range: ~12–28 pt board thickness depending on bar size and handling.

Comparison Table

| Material | Best For | Properties | Benefits | Eco Performance |

|---|---|---|---|---|

| SBS C1S/C2S (16–24 pt) | Photo-rich branding | Smooth, white, high print fidelity | Crisp logos, tiny text clarity | Widely recyclable curbside when unlaminated; FSC option available. |

| Kraft (18–24 pt) | Natural/organic lines | Unbleached, earthy texture | Hides scuffs; pairs well with spot white | Generally recyclable; minimal inks recommended. |

| Recycled chipboard (18–24 pt) | Budget-friendly runs | Grey/brown core, good stiffness | Cost-effective, sturdy | Often recyclable; verify local MRF guidance (see note in Sustainability). |

| Textured uncoated cover (14–18 pt) | Tactile branding | Linen/felt textures, muted inks | Premium handfeel | Recyclable when uncoated; avoid plastic lamination to keep recyclability high. |

| Heavy SBS (24–28 pt) | Larger or slippery bars | Extra caliper for grip | Reduces slippage; crisper scores | Recyclable; may increase postage weight slightly. |

Printing & Branding Options

We print CMYK (digital/offset) for full-color artwork and add Pantone® spot colors where brand accuracy is critical—no Pantone fee per Business Details. Offset suits longer runs and solid brand fields; digital excels at short runs, seasonal variants, and lot coding. Smart sleeve layouts put logos front, ingredients on a wide back panel, and windows aligned to hero swirls or embeds. Available embellishments include gloss/matte coatings, spot UV, foil stamping, emboss/deboss for a premium look.

Finishes & Specialty Effects

-

Soft-touch matte for a velvety, high-end touch that invites handling.

-

Hot foil (gold, rose, matte colors) to spotlight brand marks or scent names.

-

Emboss/deboss to add tactile cues on key lines (e.g., “Unscented,” “Sensitive”).

-

Spot UV over matte to pop photography or patterns without flooding the sleeve.

Soap Sleeve Styles & Customization

Pick from glued sleeves with a clean overlap seam, belly bands for ultra-minimal coverage, or windowed sleeves to showcase texture. Add micro-perfs for tear-assist, rounded corners for pocket-safe merchandise, and tape-applied peel-and-seal to speed hand assembly (½-inch tape option). Dielines include score allowances for board caliper so sleeves slide—but don’t slip.

Sizing & Technical Specs

Measure after cure: Handmade bars shrink as they dry. Wrap a paper strip around a fully cured bar, mark the join, then add seam allowance per dieline (or select the ½-inch peel-and-seal tape option). Many artisan bars cluster near ~3.5″ × 2.5″ × 1″, but we size to your exact measurements; tolerance is typically ±1/16″ on trim/score. For larger or slippery bars, step up caliper (e.g., 22–24 pt) for grip and shape retention.

Design Guidance: Soap Sleeves That Fit & Sell

-

Artboard & bleed: Build on our dieline with 0.125″ bleed and safe margins clear of folds and the glue/tape area.

-

Seam planning: Keep dense solids and fine text off the overlap; if using peel-and-seal, leave the ½″ tape zone ink-free for best adhesion.

-

Window alignment: Place windows to frame swirl peaks or embeds; add a 0.08″ safety from knife edge.

-

Labeling: Reserve a back panel for INCI, net weight (avoirdupois and metric), batch/UPC/QR, and contact info.

-

Files: Supply vector logos; embed/outline fonts; CMYK + any PMS callouts; 300+ PPI linked images; include a print-ready PDF and native file package.

How to Order Custom Soap Sleeves

- Share bar dimensions, weight/finish, and target caliper.

- Receive dieline + quote.

- Upload artwork for proof.

- Approve and enter production.

Printives Quality & Compliance for Sleeves

Paperboard options are available with FSC® chain-of-custody. Each job receives a pre-press review (bleed, overprint, color spaces) and press checks for color targets. For cosmetic labeling, we provide space for all required statements; final regulatory review remains the brand’s responsibility.

Eco-Forward Soap Sleeve Choices

Sleeves inherently use less material than full cartons. Unlaminated SBS/Kraft sleeves are widely accepted in U.S. curbside programs; coatings like AQ/UV typically remain recyclable, while plastic laminations can limit recovery—ask us to keep specs recycle-friendly.

Case Study: How Sleeves Lifted Sell-Through

An indie soap brand shifted from labels to 18-pt Kraft sleeves with a die-cut window and foil scent badge. The change cut kitting time by 32% (pre-taped seams), reduced damages in transit, and lifted wholesale sell-through after retailers reported faster shopper comparison on shelf. The brand now rotates seasonal art digitally without changing dielines—holding per-unit costs steady.

Comparison & Alternatives: Soap Sleeves vs. Boxes vs. Labels

-

Sleeves vs. full boxes: Sleeves use less material and show product texture—ideal for handmade bars and value lines. Soap Boxes fully enclose (better for brittle or high-end SKUs) but add material and assembly time.

-

Sleeves vs. labels: Labels are cheapest but can wrinkle on textured wraps and offer less billboard space. Sleeves add stiffness, hide scuffs, and create a premium “banded” look suitable for retail.

Why Choose Printives for Soap Sleeves?

Packaging-engineer support, Pantone at no fee, fast standard and rush lead times, and FSC paper options—backed by clear proofs and responsive U.S. support. We size sleeves precisely to cured-bar dimensions so your bands slide, not slip.

Frequently Asked Questions (FAQs)

Q: How do I measure my soap for a sleeve?

A: Wrap a strip of paper around a fully cured bar, mark the join, and add seam allowance (or choose ½″ peel-and-seal). We’ll translate that into a precise dieline for your stock caliper.

Q: What board thickness should I pick?

A: Most bars are happy in 16–22 pt; go 24–28 pt for larger or slick, oil-rich finishes. Thicker boards increase grip and stiffness for display.

Q: Can you match my exact brand color?

A: Yes! Pantone® matching at no fee. Provide Pantone codes and we’ll proof before print.

Q: Are sleeves recyclable?

A: Unlaminated paperboard sleeves are generally curbside-recyclable in the U.S.; verify locally. Ask us for coatings and adhesives that preserve recyclability.

Q: What’s the MOQ and lead time?

A: MOQ 100 units. Standard 10–12 business days after proof; 6–8 days rush available. Physical sample: $100, 3–4 days.

Q: Do you offer windows and special finishes?

A: Yes—custom die-cut windows, foil, emboss/deboss, soft-touch, and spot UV for statement branding.

Ready to sleeve your soaps? Send bar dimensions and branding files for a free dieline and quote. We’ll optimize caliper, fit, and finishes—then turn your order in 10–12 business days (rush 6–8). Start your custom soap sleeve project today.

Amelia J. (verified owner) –

Excellent colors and clear logo printing.

Chloe B. (verified owner) –

Love how these sleeves make my soaps stand out at markets.

Hazel K. (verified owner) –

My soaps look like they belong in a boutique now.

Addison Q. (verified owner) –

Ordered 12000 sleeves. Every one matched my brand’s Pantone colors perfectly.

Victoria A. (verified owner) –

The kraft texture pairs perfectly with natural soap recipes.

Mia P. (verified owner) –

These sleeves hug the soap perfectly. Customers love the professional feel.

Olivia W. (verified owner) –

The kraft option looks eco-friendly and fits my organic soaps perfectly.

Zoe F. (verified owner) –

Good quality sleeves, though a couple had faint marks on the edges.

Harper C. (verified owner) –

Lightweight but durable enough to hold the soaps firmly.

Natalie Z. (verified owner) –

Quick delivery, great quality, and perfect for my gift sets.

Emma T. (verified owner) –

Simple yet elegant. The soap sleeves make my handmade bars look retail-ready.

Ava N. (verified owner) –

Ordered 500 pieces for a fair — quick turnaround and flawless finish.

Abigail H. (verified owner) –

Affordable bulk order, and all 2000 sleeves looked consistent.

Lily M. (verified owner) –

Ordered a small batch first (250 pieces) and the quality convinced me to reorder in bulk.

Evelyn D. (verified owner) –

The matte finish gives a premium look without being flashy.

Hannah L. (verified owner) –

Printing was exactly as I imagined — vibrant and sharp.

Grace V. (verified owner) –

Very easy to slide onto the soap bars, no tearing at all.

Isabella G. (verified owner) –

Nice quality overall, but a few sleeves had slightly lighter print than the sample.

Sophia R. (verified owner) –

Ordered 300 sleeves and every one of them came out perfect. Branding looks sharp and consistent.

Ellie S. (verified owner) –

Strong sleeves, eco-friendly material. Fits my brand image.